In the world of axe aficionados the name Gransfors Bruks gets a lot of respect, almost religious reverence. For good reason. In a time when most axes are cheap commodity items, made of questionable steel and cranked out by the thousands for sale in big box stores, Gransfors Bruks' axes are produced with a level of skill and attention to detail that is not found anywhere else in the axe manufacturing world.

I stumbled on this great video on YouTube this morning and thought I'd share it. If you have any interest at all in how large metal objects like axe heads are forged this is an interesting demonstration.

To be honest, most folks today don't really have a need for an axe. Nobody is going to go out and clear an acre of land with a hand axe. That's what chainsaws are for. The axe is very much a niche item, particularly one as nicely made as a Gransfors Bruks. But, there are still people that use them regularly. For some tasks like limbing downed trees, splitting firewood or rough shaping logs the axe is still the ideal tool. Agencies like the US Forest Service still use axes extensively - for jobs like backwoods trail maintenance it is easier to strap an axe to a backpack and carry it 30 miles into the brush to clear downed trees from hiking trails than it is to haul in a chainsaw, gas, oil, protective gear, a sharpening kit, etc. to do the same job.

Now, while I'm saying that most folks don't need an axe these days there certainly is no harm in having one or two ready to go in case that errant tree falls and blocks your driveway. Or you finally decided to build that log cabin in the back yard. Or carve out that Viking longboat you've been thinking about.

I don't have a Gransfors Bruks in my small axe collection. After watching this video I think I might just have to correct that shortcoming.

Stay sharp!

Brian

Awww geeze, not another blog!

Welcome to A Fine Blade!

This blog will focus one of my lifelong passions and one of man's most basic tools - the knife!

As time and events permit we'll tiptoe into other territory where we can use the knife as a metaphor in discussions about current events and have a little politically incorrect fun.

Because you see, knives rank just below guns as the most politically incorrect subject on the web today.

Guns & Knives = Bad. Gay Marriage & Recreational Drug Use = Good

We'll see if we can't have some fun with that.

So stay tuned, and welcome aboard!

Monday, September 26, 2011

Sunday, September 25, 2011

An Epic Encounter

Or is that an EPIC encounter?

Yesterday I was working the Georgia Chapter of Trout Unlimited at the EPIC Outdoor Game Fair at the Foxhall Estates outside of Atlanta. My friend Bill, who was working with me at the Trout Unlimited booth, said "Hey, Buck Knives has a booth in the vendor's tent!" That's all I needed to hear. We made a beeline for the tent and, sure enough, Buck was all set up with an outstanding display.

I'm a sucker for a Buck knife - any Buck knife - so this fellow sold me one.

C.J. Buck is the great-grandson of Hoyt Buck, the founder of Buck Knives, and is the current President and CEO of the company. He's also a great guy, and easily spent 15 minutes talking fly fishing with Bill.

How was the rest of the show? Great, if your interest is over/under shotguns that cost more than a house (that's more than a house, not a house payment), single malt scotches, polo ponies and African safaris. I was way out of my economic and social class league. But it was fun to see how the evil rich (ya' know, them's that don't pay their fair share) amuse themselves.

I do have to give a shout out to another great guy, Bill Oyster of Oyster Fly Rods. Bill had his excellent display set up and spent a good bit of time talking bamboo rods with my friend Bill and I. Bill Oyster is a legend among Georgia fly fishermen. He's personable, friendly and open, and will share just about anything related to the craft of bamboo fly rod making. He also has a little trick he uses to show how sturdy bamboo rods are. He'll lay one of his pieces of work on a hard surface and jump on it with both feet. When he does that fly fishermen around the world cringe, but Bill does it to demonstrate just how solid a properly made bamboo rod truly is. They may be expensive, but they ain't delicate.

Here's Bill giving a short class on the steps involved in bamboo fly rod construction.

Stay sharp!

Brian

Yesterday I was working the Georgia Chapter of Trout Unlimited at the EPIC Outdoor Game Fair at the Foxhall Estates outside of Atlanta. My friend Bill, who was working with me at the Trout Unlimited booth, said "Hey, Buck Knives has a booth in the vendor's tent!" That's all I needed to hear. We made a beeline for the tent and, sure enough, Buck was all set up with an outstanding display.

I'm a sucker for a Buck knife - any Buck knife - so this fellow sold me one.

|

| C.J. Buck (left) and Bill |

|

| C.J. and Bill talking about fly fishing |

I do have to give a shout out to another great guy, Bill Oyster of Oyster Fly Rods. Bill had his excellent display set up and spent a good bit of time talking bamboo rods with my friend Bill and I. Bill Oyster is a legend among Georgia fly fishermen. He's personable, friendly and open, and will share just about anything related to the craft of bamboo fly rod making. He also has a little trick he uses to show how sturdy bamboo rods are. He'll lay one of his pieces of work on a hard surface and jump on it with both feet. When he does that fly fishermen around the world cringe, but Bill does it to demonstrate just how solid a properly made bamboo rod truly is. They may be expensive, but they ain't delicate.

Here's Bill giving a short class on the steps involved in bamboo fly rod construction.

|

| Splitting cane |

|

| Discussing bamboo properties |

|

| Discussing tapers |

|

| Setting tapers on the planing jig |

Stay sharp!

Brian

Sunday, September 18, 2011

Blade Of The Month - Cold Steel Pendleton Lite Hunter

I'm a sucker for a good knife that is also inexpensive. With modern materials and production methods it is possible for today's manufacturers to crank out great knives at low cost. All they have to do is put some thought into the design.

I'm also one of those guys who constantly asks "how low can you go?" How cheaply can a manufacturer bring a truly outstanding design to market? Well, today we are going to look at what is, in my opinion, the single best low cost knife on the market today. It has all competition beat in terms of design and execution. It is the current 'How Low Can You Go?' champ. The Cold Steel Pendleton Lite Hunter

This knife is a low cost version of the Cold Steel Pendleton Hunter, itself a great knife. This knife was designed by custom knifemaker Lloyd Pendleton and has been in the Cold Steel lineup for a number of years.

Cold Steel has a reputation for producing some really nice low priced knives. They leverage their relationships with manufacturers in the Far East to re-interpret some famous designs using less expensive materials and manufacturing processes. That is how we got the Pendleton Lite Hunter. In comparison with the original Pendleton Hunter this knife sports a simpler molded handle, the blade is made of a lower-cost (and thinner) steel - Krupp 4116 - that is stamped instead of ground. Krupp 4116 is widely used in the kitchen cutlery industry so it's a proven steel. Krupp 4116 isn't a sexy steel like Cold Steel's San Mai laminate, but it works just fine in the real world. The sheath is a simple nylon pouch style that is used with several other Cold Steel knife designs like the Finn Bear, so there's a big cost savings there.

What I also suspect, but can't confirm, is that this knife is not a full tang design. My guess is that the tang only runs part way into the handle, a common compromise with lower cost knives.

Update! I recently contacted Cold Steel and asked whether or not the Pendleton Lite Hunter has a full tang. Here's the reply from Anthony Russell in Cold Steel's Customer Service Department:

"The tang goes just over 1/2 way to the end of the handle, and the handle is injection molded around the tang. The tang is also "keyed" into the [handle] for added strength."

So as I suspected it is not a full tang knife. It's not a problem, just good to know.

What the Pendleton Lite Hunter retains from the original is the excellent blade profile and handle shape. The blade incorporates a slight upsweep along the spine that results in a deeper edge belly and reinforced tip. The handle is extremely comfortable in a multitude of positions. In fact, I think I like the Pendleton Lite Hunter's handle more than the original model. The handle shape and texture is very reminiscent of the excellent cast aluminum handles Pete Gerber used to put on his classic knives like the Gerber A-400.

The knife is very light, very comfortable in the hand and very easy to use.

The sheath is also a pleasant surprise. It is a simple pouch design that is very well constructed and is a very effective design. The sheath is made of stiff nylon that is stitched and riveted and it incorporates a thick spine to help it hold its shape. It ain't fancy, but it does precisely what a knife sheath is supposed to do - hold the knife securely and protect the user from the blade.

So how much does all this goodness cost? This morning I checked prices on the web and found you can buy this knife from Amazon.com for a whopping $13.72!

Stay sharp!

Brian

I'm also one of those guys who constantly asks "how low can you go?" How cheaply can a manufacturer bring a truly outstanding design to market? Well, today we are going to look at what is, in my opinion, the single best low cost knife on the market today. It has all competition beat in terms of design and execution. It is the current 'How Low Can You Go?' champ. The Cold Steel Pendleton Lite Hunter

|

| Cold Steel Pendleton Lite Hunter |

This knife is a low cost version of the Cold Steel Pendleton Hunter, itself a great knife. This knife was designed by custom knifemaker Lloyd Pendleton and has been in the Cold Steel lineup for a number of years.

Cold Steel has a reputation for producing some really nice low priced knives. They leverage their relationships with manufacturers in the Far East to re-interpret some famous designs using less expensive materials and manufacturing processes. That is how we got the Pendleton Lite Hunter. In comparison with the original Pendleton Hunter this knife sports a simpler molded handle, the blade is made of a lower-cost (and thinner) steel - Krupp 4116 - that is stamped instead of ground. Krupp 4116 is widely used in the kitchen cutlery industry so it's a proven steel. Krupp 4116 isn't a sexy steel like Cold Steel's San Mai laminate, but it works just fine in the real world. The sheath is a simple nylon pouch style that is used with several other Cold Steel knife designs like the Finn Bear, so there's a big cost savings there.

What I also suspect, but can't confirm, is that this knife is not a full tang design. My guess is that the tang only runs part way into the handle, a common compromise with lower cost knives.

___________________________________________________

Update! I recently contacted Cold Steel and asked whether or not the Pendleton Lite Hunter has a full tang. Here's the reply from Anthony Russell in Cold Steel's Customer Service Department:

"The tang goes just over 1/2 way to the end of the handle, and the handle is injection molded around the tang. The tang is also "keyed" into the [handle] for added strength."

So as I suspected it is not a full tang knife. It's not a problem, just good to know.

___________________________________________________

What the Pendleton Lite Hunter retains from the original is the excellent blade profile and handle shape. The blade incorporates a slight upsweep along the spine that results in a deeper edge belly and reinforced tip. The handle is extremely comfortable in a multitude of positions. In fact, I think I like the Pendleton Lite Hunter's handle more than the original model. The handle shape and texture is very reminiscent of the excellent cast aluminum handles Pete Gerber used to put on his classic knives like the Gerber A-400.

The knife is very light, very comfortable in the hand and very easy to use.

The sheath is also a pleasant surprise. It is a simple pouch design that is very well constructed and is a very effective design. The sheath is made of stiff nylon that is stitched and riveted and it incorporates a thick spine to help it hold its shape. It ain't fancy, but it does precisely what a knife sheath is supposed to do - hold the knife securely and protect the user from the blade.

So how much does all this goodness cost? This morning I checked prices on the web and found you can buy this knife from Amazon.com for a whopping $13.72!

Stay sharp!

Brian

Tuesday, August 16, 2011

The Case Congress Knife

I stumbled across this video on YouTube this morning. Two observations:

1. The Case Congress knife is bee-utiful!

2. I've never seen a video made by this guy before, but it is obvious he understands the concept of production values. While he's clearly not from around here, he speaks better English than 99% of the fanboys posting their garbage on the web.

A great review and a great historical perspective. Enjoy!

Guess what's next on my shopping list.

Stay sharp!

Brian

1. The Case Congress knife is bee-utiful!

2. I've never seen a video made by this guy before, but it is obvious he understands the concept of production values. While he's clearly not from around here, he speaks better English than 99% of the fanboys posting their garbage on the web.

A great review and a great historical perspective. Enjoy!

Guess what's next on my shopping list.

Stay sharp!

Brian

Sunday, August 14, 2011

The Buck Folding Hunter

|

| Buck 110 Folding Hunter This is a current production standard model with ebony handle scales and brass bolsters |

One of the benefits of being a member of the Buck Collectors Club is that you get access to Buck's production numbers for specific models of knives. As I was poking around the club's website I hit on the numbers for the Buck 110 Folding Hunter. I was surprised to read that since it's introduction in 1964 Buck has produced over 10 million of the standard model Folding Hunter! When you consider that Buck also makes several other versions of this model - versions with special blade steel, fancy bolster and handle material and even a very popular plastic handled version (the BuckLite) total production is probably closer to 12 million. Buck claims that this is the most popular folding knife in the world, and I believe 'em.

This Buck was a ubiquitous knife in the circles I traveled in. Just about every Soldier carried a Folding Hunter of one style or another. If you held a formation and told everyone to lift their BDU blouses to show what they were wearing on their belt about half would have a Folding Hunter resting there. Me included. My first Folding Hunter was bought around 1979 and promptly lost. A year or two later, when this struggling second lieutenant could afford it, I went out to the PX and bought a replacement.

The Folding Hunter is one of those rare products that has both improved and gotten cheaper over time. The retail price of a Folding Hunter in 1965 was $16. Adjusted for inflation that same $16 dollar knife should cost $114 today. Yet you can walk into most Wal-Marts in the US and purchase this same knife for less than $30. High production volume, production experience and automation have made their mark here. Buck can crank out these knives at an incredibly low price yet keep quality very high.

As to quality - it is clear that Buck does a much better job of finishing these knives today than they did 30 years ago. My 1982 example has a very square, chunky profile and using it for hard tasks can be a bit uncomfortable. My 2011 example has a nicely rounded handle and frame and is one of the most comfortable to hold knives I have in my collection.

But just how well do they hold up in the real world? If my 1982 Folding Hunter is a fair example of the breed then I can say without hesitation they hold up very, very well. This particular knife has been used to cut manila rope, nylon webbing, and aluminum communications wire. It has carved tent stakes and aiming stakes. It was used more than once to dig small holes. It has cut up any number of Army issue slabs of ham, chicken (yes, in the Army even chicken comes in slabs) salisbury steak, blueberry cobbler and pumpkin pie. It has sliced open hundreds of MRE bags, cut parachute suspension lines and tent canvas, scraped carbon build-up off of M-16 bolt carriers and served as a pointer during briefings. It has sliced open hundreds of sandbags, a particularly tough test of a knife's edge holding ability. It has carved open aluminum soda cans to make strobe light covers and emergency cook stoves. It has been used as a paperweight and as a dead-weight to do river depth soundings. It has caved the husk off of coconuts and chopped bamboo. On more than one occasion it was used as a hammer. It carries the scars of 30 years of proud service; the blade is scratched and scuffed and the brass bolsters are dinged and gouged. It desperately needs a good edge re-grinding and sharpening, but it snaps open and locks up with authority and the blade is as tight in the frame as it was the day I bought it. It is an honorable veteran that has earned its retirement.

|

| Buck Folding Hunters From top to bottom - 1982 production Model 110, 2011 Model 110 and a Model 426 (BuckLite) with a composite plastic handle |

The point here isn't that the Buck Folding Hunter is a good, cheap knife. Rather, it is a great knife that stands up to rough use yet is inexpensive enough that the owner doesn't feel he has to baby it. Thirty dollars buys you a whole lot of knife.

The Folding Hunter astounded the knife world when it was introduced. At first the Buck board of directors was very reluctant to approve production - they really did not see a market for the knife. I believe it was Chuck Buck that convinced them to give it a try. Chuck figured this knife would sell well with hunters who would use it just a few weeks each year. It turns out Chuck was flat wrong - but in a good way. The Folding Hunter took off in ways Buck never imagined. It proved immediately popular not just with hunters but with the military, policemen, firemen, tradesmen, and just about anybody that lived, worked or spent time in the outdoors. Demand exploded and caught the knife industry by surprise. Almost every other knife manufacturer scrambled to get their version of a large, single blade lockback knife into production. Most were very good in their own right, but none ever approached the popularity of the Buck Folding Hunter. It was there first and has stayed first for almost 50 years.

There you have it! The Buck Folding Hunter. A classic knife from an iconic American company.

Stay sharp!

Brian

Saturday, August 13, 2011

Would Congress Sell You a Congress Knife?

Not these days.

There is a very distinctive pocket knife pattern known as the 'congress pattern'. It has been around since the mid-1800s. Lots of folks on hearing the name assume it is somehow directly linked to the US Congress. Perhaps it was a style of knife officially adopted by Congress? Or presented by Congress on special occasions? That is nice to think about - our august and beneficent Congress officially adopting a knife. Unfortunately there is no record I can find proving that Congress ever officially adopted anything with a sharp edge on it. The true story behind the congress pattern knife seems to be more of a self-fulfilling wish.

In the early 1800s the cutlery firms out of Sheffield, England were pouring knives and cutlery products into the young United States to fulfill an almost insatiable demand for quality blades. At the time the US was still an agrarian society and was expanding fast, first up over the Appalachians and into the old Northwest Territories (the upper midwest), then into the Louisiana Purchase. Land was cheap and fertile and a hardworking family could easily support themselves on a modest sized farm. There were few labor saving devices in those days and everything on the farm was done by hand or horse power. Most farm tasks involved a cutting edge - a knife, axe, saw, even a plow blade. Local blacksmiths and small manufacturers in the eastern US handled the 'rough trade' implements; axes, hatchets, butcher knives, saw blades, etc., but there was still a demand for finer cutlery that American manufacturers couldn't meet - quality kitchen cutlery, fine hunting knives and well made pocket knives. This is the market the Sheffield cutlers dominated. Sheffield cutlery had an almost mystical reputation; English crucible steel was the best production steel available at the time and Sheffield's skilled workforce could turn out an amazing range and volume of high quality knives and tools to meet specific needs. The blade stamp 'Sheffield' was considered a hallmark of superior quality and American customers selected Sheffield products before all others.

The cutlery firms of Sheffield were also marketing geniuses. Lets face it, the average 19th century farm laborer or office clerk really only needed one pocket knife in his life - something to cut up his lunchtime slab of roast beef or ham and to whittle a new nib on his quill pen. A pocket knife was a durable consumer item - something that didn't wear out in use and lasted years or decades. The Sheffield firms needed to convince consumers that they just HAD to have a new knife long before the old one wore out - they needed to build steady, repeat demand. The cutlery firms hit on a brilliant marketing gimmick - the concept of the cosmetic upgrade.

More than a century before the marketing wizards of Detroit put the same plan into action, the cutlery firms of Sheffield figured out that if you gussy up a plain knife just a bit - add mother of pearl handles or silver bolsters, or put a better polish on the blade - they could more readily catch the eye of the young dandy who was doing a little window shopping. Maybe he was tired of looking at the old, scuffed up wooden handled knife he carried around in his pocket and that new, shiny, fancy knife was just what he needed to impress his girl. It was all eye candy appeal, and damn if it didn't work!

Then they took it to the next level. The Sheffield firms hit on the idea of generating the perception that specific tasks demanded very specific cutting blade styles. Any old pocket knife can slice open a letter, but the cutlers of Sheffield implied that only a specially designed desk knife with a letter opening blade can get the job done done with elegance and style. No true gentleman should ever be caught opening important correspondence with a plain old pocket knife. It was undignified! Similarly, while any old pocket knife can slice up a pear or an apple the cutlers of Sheffield impressed upon their scruffy American cousins the notion that only a knife with a specially designed blade is suitable to the elegant task of carving up the dessert fruit. It would be just so ungentlemanly to let your lady see you slice up those delicate grapes with the same pocket knife you used to clean your fingernails. Only a specially designed Sheffield fruit knife was correct for the task. Oh, you unwashed masses! You have so much to learn (and so much money to spend). Let the master cutlers of Sheffield bring elegance and orderliness into your lives!

The 19th century cutlery catalogs put out by the Sheffield firms show a bewildering array of knives. The combinations of blade styles and finishes are endless. Pocket knives for camping, cooking, carving and castrating. Doctor's pocket knives for doing emergency surgery. Whittling knives for turning big sticks into little sticks. Pruning knives for tending the garden. Farriers knives with a folding pick for cleaning your horse's hooves. Delicate little bird knives that slip comfortably into the vest pocket on upland game hunts. Knives for cutting tobacco leaf and knives for clipping the end off of a fine cigar.

Out of this crazy mix of blade styles and finishes emerged the knife known as the 'congress pattern'. It appears the name was merely a marketing device first used by Joseph Rodgers & Sons sometime before the mid-1800s. It was originally a four blade knife with edges suited for shaping pen nibs and carving and whittling. I guess the marketing guys at Joseph Rodgers figured that's all that American congressmen did with their time - whittle on wooden sticks and sharpen quill pen nibs. Thus the congress pattern knife was born.

A funny thing happened on the way to the Capitol Building. The knife proved so popular that people naturally assumed the congress pattern was what congressmen carried and that it was somehow endorsed by the US Congress. After all, who wouldn't want to own the very same knife that their local congressman carried? It helped that it was also a very good design with a great combination of useful blades. In one of the classic examples of advertising shaping reality a lot of congressmen - senators and representatives - ended up carrying and using the congress pattern knife. In fact, one of America's greatest presidents and an acknowledged knife and gun enthusiast regularly carried this knife. No, not Teddy Roosevelt. Abraham Lincoln! The night he was assassinated in Ford's Theater he had a congress pattern knife in his pocket. That knife is now on display in the Library of Congress.

[Editorial aside here. Yes Virginia, Abraham Lincoln was a big gun and knife enthusiast. He loved reviewing new weapons patents and often invited gun makers to demonstrate their new inventions right on the grounds of the White House. He was fascinated by the Henry Rifle design and pushed the War Department to adopt it during the Civil War. That was probably the last time a gun was fired for sport or pleasure on the grounds of the White House.]

A question that is often asked is whether or not the congress pattern knife was ever sold in the gift shops in the US Capitol Building. I don't think anyone can say for sure, but what we do know is that right up through the early 1980s various commemorative pocket knives were offered for sale in the gift shops. While visiting the Capitol on several occasions in the early 80's I clearly remember seeing pocket knives for sale. In his classic book 'The Practical Book of Knives' the author Ken Warner shows a Schrade Uncle Henry stockman pattern knife he bought in the Senate shop in the Capitol. So, I think it's a fair assumption to say that at some point a congress pattern knife was offered for sale in the US Capitol. But those days are far behind us. I'm sure that today in a building filled with dull minds there are no sharp things on offer.

While not as popular as it once was, the congress pattern knife is still available from a number of manufacturers. Case Cutlery, the premier US pocket knife manufacturer, offers several styles in their current catalog. It is a good pattern and it still sells well.

Recently I came across a congress pattern knife offered by CRKT (Columbia River Knife and Tool). I've owned several of their other pocket knife offerings and they are all very well done. I decided to order one up and when it arrived I became fascinated by the knife's design and history (and hence this blog post!).

As much as I love stockman pattern pocket knives, this congress pattern could steal me away. One thing is certain, I'll have to get my hands on a few more to help me make up my mind.

Stay sharp!

Brian

There is a very distinctive pocket knife pattern known as the 'congress pattern'. It has been around since the mid-1800s. Lots of folks on hearing the name assume it is somehow directly linked to the US Congress. Perhaps it was a style of knife officially adopted by Congress? Or presented by Congress on special occasions? That is nice to think about - our august and beneficent Congress officially adopting a knife. Unfortunately there is no record I can find proving that Congress ever officially adopted anything with a sharp edge on it. The true story behind the congress pattern knife seems to be more of a self-fulfilling wish.

In the early 1800s the cutlery firms out of Sheffield, England were pouring knives and cutlery products into the young United States to fulfill an almost insatiable demand for quality blades. At the time the US was still an agrarian society and was expanding fast, first up over the Appalachians and into the old Northwest Territories (the upper midwest), then into the Louisiana Purchase. Land was cheap and fertile and a hardworking family could easily support themselves on a modest sized farm. There were few labor saving devices in those days and everything on the farm was done by hand or horse power. Most farm tasks involved a cutting edge - a knife, axe, saw, even a plow blade. Local blacksmiths and small manufacturers in the eastern US handled the 'rough trade' implements; axes, hatchets, butcher knives, saw blades, etc., but there was still a demand for finer cutlery that American manufacturers couldn't meet - quality kitchen cutlery, fine hunting knives and well made pocket knives. This is the market the Sheffield cutlers dominated. Sheffield cutlery had an almost mystical reputation; English crucible steel was the best production steel available at the time and Sheffield's skilled workforce could turn out an amazing range and volume of high quality knives and tools to meet specific needs. The blade stamp 'Sheffield' was considered a hallmark of superior quality and American customers selected Sheffield products before all others.

The cutlery firms of Sheffield were also marketing geniuses. Lets face it, the average 19th century farm laborer or office clerk really only needed one pocket knife in his life - something to cut up his lunchtime slab of roast beef or ham and to whittle a new nib on his quill pen. A pocket knife was a durable consumer item - something that didn't wear out in use and lasted years or decades. The Sheffield firms needed to convince consumers that they just HAD to have a new knife long before the old one wore out - they needed to build steady, repeat demand. The cutlery firms hit on a brilliant marketing gimmick - the concept of the cosmetic upgrade.

More than a century before the marketing wizards of Detroit put the same plan into action, the cutlery firms of Sheffield figured out that if you gussy up a plain knife just a bit - add mother of pearl handles or silver bolsters, or put a better polish on the blade - they could more readily catch the eye of the young dandy who was doing a little window shopping. Maybe he was tired of looking at the old, scuffed up wooden handled knife he carried around in his pocket and that new, shiny, fancy knife was just what he needed to impress his girl. It was all eye candy appeal, and damn if it didn't work!

Then they took it to the next level. The Sheffield firms hit on the idea of generating the perception that specific tasks demanded very specific cutting blade styles. Any old pocket knife can slice open a letter, but the cutlers of Sheffield implied that only a specially designed desk knife with a letter opening blade can get the job done done with elegance and style. No true gentleman should ever be caught opening important correspondence with a plain old pocket knife. It was undignified! Similarly, while any old pocket knife can slice up a pear or an apple the cutlers of Sheffield impressed upon their scruffy American cousins the notion that only a knife with a specially designed blade is suitable to the elegant task of carving up the dessert fruit. It would be just so ungentlemanly to let your lady see you slice up those delicate grapes with the same pocket knife you used to clean your fingernails. Only a specially designed Sheffield fruit knife was correct for the task. Oh, you unwashed masses! You have so much to learn (and so much money to spend). Let the master cutlers of Sheffield bring elegance and orderliness into your lives!

The 19th century cutlery catalogs put out by the Sheffield firms show a bewildering array of knives. The combinations of blade styles and finishes are endless. Pocket knives for camping, cooking, carving and castrating. Doctor's pocket knives for doing emergency surgery. Whittling knives for turning big sticks into little sticks. Pruning knives for tending the garden. Farriers knives with a folding pick for cleaning your horse's hooves. Delicate little bird knives that slip comfortably into the vest pocket on upland game hunts. Knives for cutting tobacco leaf and knives for clipping the end off of a fine cigar.

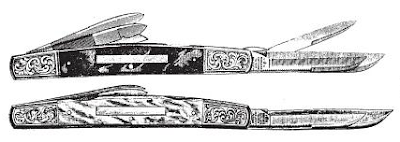

Out of this crazy mix of blade styles and finishes emerged the knife known as the 'congress pattern'. It appears the name was merely a marketing device first used by Joseph Rodgers & Sons sometime before the mid-1800s. It was originally a four blade knife with edges suited for shaping pen nibs and carving and whittling. I guess the marketing guys at Joseph Rodgers figured that's all that American congressmen did with their time - whittle on wooden sticks and sharpen quill pen nibs. Thus the congress pattern knife was born.

|

| Joseph Rodgers & Sons congress pattern pocket knife. From a late 19th century cutlery catalog. |

A funny thing happened on the way to the Capitol Building. The knife proved so popular that people naturally assumed the congress pattern was what congressmen carried and that it was somehow endorsed by the US Congress. After all, who wouldn't want to own the very same knife that their local congressman carried? It helped that it was also a very good design with a great combination of useful blades. In one of the classic examples of advertising shaping reality a lot of congressmen - senators and representatives - ended up carrying and using the congress pattern knife. In fact, one of America's greatest presidents and an acknowledged knife and gun enthusiast regularly carried this knife. No, not Teddy Roosevelt. Abraham Lincoln! The night he was assassinated in Ford's Theater he had a congress pattern knife in his pocket. That knife is now on display in the Library of Congress.

|

| The contents of Abraham Lincoln's pockets on the night he was assasinated at Ford's Theater. Note the distinctive congress pattern pocket knife. From the Library of Congress 'Artifacts of Assassination' on-line display |

[Editorial aside here. Yes Virginia, Abraham Lincoln was a big gun and knife enthusiast. He loved reviewing new weapons patents and often invited gun makers to demonstrate their new inventions right on the grounds of the White House. He was fascinated by the Henry Rifle design and pushed the War Department to adopt it during the Civil War. That was probably the last time a gun was fired for sport or pleasure on the grounds of the White House.]

A question that is often asked is whether or not the congress pattern knife was ever sold in the gift shops in the US Capitol Building. I don't think anyone can say for sure, but what we do know is that right up through the early 1980s various commemorative pocket knives were offered for sale in the gift shops. While visiting the Capitol on several occasions in the early 80's I clearly remember seeing pocket knives for sale. In his classic book 'The Practical Book of Knives' the author Ken Warner shows a Schrade Uncle Henry stockman pattern knife he bought in the Senate shop in the Capitol. So, I think it's a fair assumption to say that at some point a congress pattern knife was offered for sale in the US Capitol. But those days are far behind us. I'm sure that today in a building filled with dull minds there are no sharp things on offer.

While not as popular as it once was, the congress pattern knife is still available from a number of manufacturers. Case Cutlery, the premier US pocket knife manufacturer, offers several styles in their current catalog. It is a good pattern and it still sells well.

Recently I came across a congress pattern knife offered by CRKT (Columbia River Knife and Tool). I've owned several of their other pocket knife offerings and they are all very well done. I decided to order one up and when it arrived I became fascinated by the knife's design and history (and hence this blog post!).

|

| The CRKT Congress Pattern Knife |

|

| Blades out! An extremely useful combination of blades. No wonder this pattern was so popular. |

Stay sharp!

Brian

Sunday, July 31, 2011

Knives For An Empire

For most of the 19th and early 20th Century the British knifemakers of Sheffield dominated the cutlery trade. The British steel making industry developed and matured fairly early. The English were making production lots of blister and crucible steel well before the Bessemer Process was invented in the 1850s, and a robust cutlery industry developed to take advantage of the high quality steel being produced.

It helped that English knifemakers had a ready worldwide market - the British Empire and an eager American market that could not be satisfied (yet) by the fledgling US cutlery industry.

The cutlers of Sheffield produced some of the finest knives ever seen, and their products were always in high demand even after cutlery manufacturing in the US and Germany (Solingen) matured in the late 1800s. The blade stamp 'Sheffield' was a hallmark of quality as much as it was a mark of origin.

Much of the work was piecework, with the manufacturing steps divided into forging, grinding, assembly, fitting and polishing. The bladesmiths, grinders and assemblers were skilled tradesmen who often worked as independent contractors to large production houses. They served up to seven year apprenticeships and were masters of their crafts.

This film shows the steps involved in making a folding blade knife. I believe it was filmed in Sheffield right after WWII based on some visual clues I noted while watching it. It is a historical record of a process that, I'm sure, has long since died away - that of the individual cutler producing a product under the old piecework system. The sound isn't too good but the narration is an important part of the story, so turn it up and listen closely!

Alas, cutlery production died off quickly in Sheffield during WWI. The reason was frighteningly simple - most of the cutlers, the cream of British knifemaking, were inducted into the hometown army regiments that pulled members from the Sheffield region. These regiments were fed into the battlefield slaughter at places like The Somme and almost overnight an entire generation of master cutlers was wiped out. Sheffield never recovered.

Sheffield remained an important cutlery production center, but the loss of trained personnel meant greatly reduced production and Sheffield started to lose its market share. The American cutlery industry raced to fill the market void and never looked back.

It helped that English knifemakers had a ready worldwide market - the British Empire and an eager American market that could not be satisfied (yet) by the fledgling US cutlery industry.

The cutlers of Sheffield produced some of the finest knives ever seen, and their products were always in high demand even after cutlery manufacturing in the US and Germany (Solingen) matured in the late 1800s. The blade stamp 'Sheffield' was a hallmark of quality as much as it was a mark of origin.

Much of the work was piecework, with the manufacturing steps divided into forging, grinding, assembly, fitting and polishing. The bladesmiths, grinders and assemblers were skilled tradesmen who often worked as independent contractors to large production houses. They served up to seven year apprenticeships and were masters of their crafts.

This film shows the steps involved in making a folding blade knife. I believe it was filmed in Sheffield right after WWII based on some visual clues I noted while watching it. It is a historical record of a process that, I'm sure, has long since died away - that of the individual cutler producing a product under the old piecework system. The sound isn't too good but the narration is an important part of the story, so turn it up and listen closely!

Alas, cutlery production died off quickly in Sheffield during WWI. The reason was frighteningly simple - most of the cutlers, the cream of British knifemaking, were inducted into the hometown army regiments that pulled members from the Sheffield region. These regiments were fed into the battlefield slaughter at places like The Somme and almost overnight an entire generation of master cutlers was wiped out. Sheffield never recovered.

Sheffield remained an important cutlery production center, but the loss of trained personnel meant greatly reduced production and Sheffield started to lose its market share. The American cutlery industry raced to fill the market void and never looked back.

Subscribe to:

Posts (Atom)